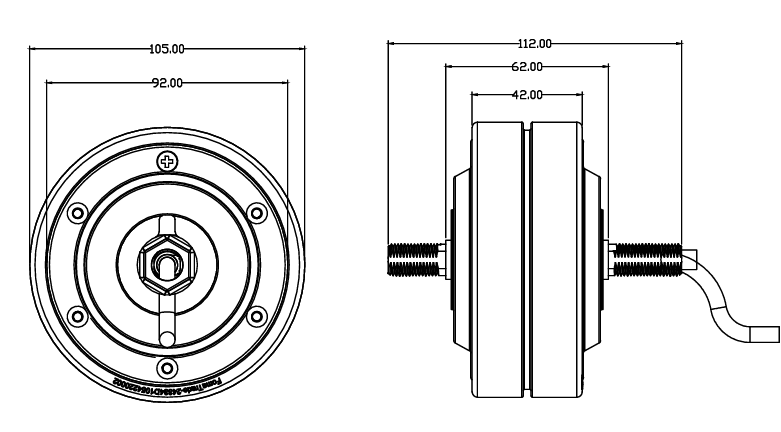

4-inch motor specifically designed for smart luggage: 105mm diameter x 42mm width, custom-made to perfectly match luggage wheel specifications; PU tread with water guide grooves for enhanced anti-slip performance and durability in wet conditions; 62mm gear opening + double-sided threaded shaft, supporting standardized assembly, eliminating the need for secondary processing and ensuring efficient installation; suitable for smart towing and automatic following luggage