| Number | Projects | Specification | Remarks |

|---|---|---|---|

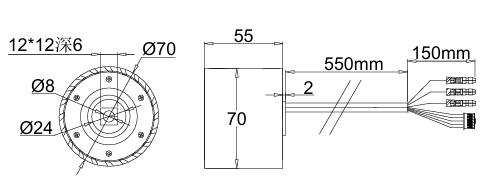

| 1 | Motor diameter | 70mm (slight deviation including tire size) | Subject to actual product |

| 2 | Rated voltage | 24V | |

| 3 | Rated power | 150W | |

| 4 | Rated rotating speed | 1600±50rpm | |

| 5 | Rated current | 5±0.5A | |

| 6 | Theoretical torque | 2.9N/M | |

| 7 | Degree of phases | 60° | |

| 8 | Number of poles | 7 pole pairs | 14PCS |

| 9 | Out of the shaft | Central hole 8mm | |

| 10 | Lead exposed | 300mm | |

| 11 | Size of connectors | Bullet connector + XH terminal 2.0 connector | |

| 12 | Brake mode | Electromagnetic brake | |

| 13 | Shaft material | 45# steel (quenched and tempered) | |

| 14 | Waterproof rating | IP55 | |

| 15 | Maximum load | 50kg | |

| 16 | Environmental requirements | -20℃ to 65℃ |