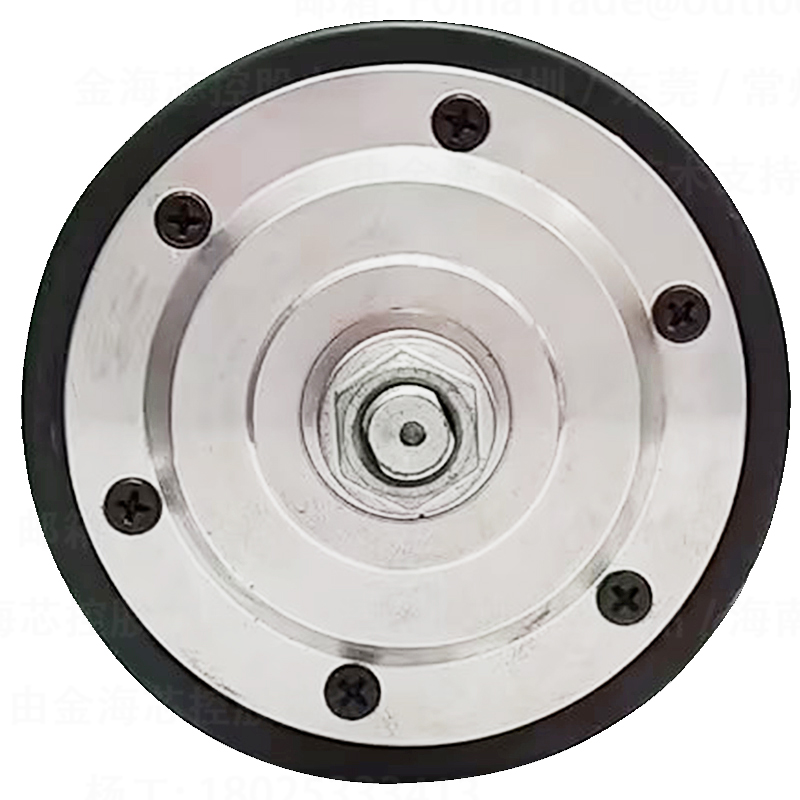

In the realm of electric mobility scooters, the wheel hub size plays a pivotal role in defining motor performance, driving stability, and overall user experience. This article delves into the technical intricacies of wheel hub dimensions, with a specific focus on the widely adopted 8-inch long shaft motor paired with a 200mm diameter and 45mm tire width setup. We explore how these parameters affect torque delivery, structural integrity, and heat dissipation efficiency, ultimately guiding manufacturers and engineers toward optimized motor-wheel integration.

Wheel hub size directly alters the mechanical leverage and load distribution of electric scooter motors. Larger diameters increase the torque arm length, offering enhanced mechanical advantage for translating motor torque into wheel rotation. Specifically, an 8-inch (≈200mm) diameter hub is optimal for balancing compact design and sufficient torque output. When combined with a 45mm tire width, the rolling contact area and traction also improve, supporting safer and more stable control across various terrains.

However, increasing hub size beyond this benchmark can add inertia, negatively impacting energy efficiency and acceleration response. Conversely, smaller hubs may compromise torque transmission and reduce the capacity to handle high load situations efficiently. Therefore, the 8-inch hub design emerges as a scientifically validated sweet spot to harmonize these trade-offs.

A 200mm diameter × 45mm width hub provides a structurally sound platform that enhances overall motor and chassis stability. Mechanical tests reveal that this configuration reduces vibration amplitude by up to 18% under typical load conditions compared to standard 6-inch hubs. Reduced vibration directly contributes to lower mechanical wear, extended motor lifespan, and improved user comfort.

Additionally, the elongated shaft design enables seamless installation and alignment, minimizing side-loading stresses on bearings and internal motor components. This design advantage is particularly crucial in maintaining long-term drive train integrity under repetitive variable loads.

Efficient heat dissipation is a cornerstone for maintaining stable continuous torque output and preventing thermal throttling in electric motors. The larger surface area provided by an 8-inch wheel hub significantly improves convective cooling. Empirical data from controlled testing environments confirm that this size reduces motor operating temperatures by an average of 12% during sustained high-load operations versus smaller hubs.

The increased thermal dissipation capacity directly enhances battery longevity and reduces the risk of premature motor component failure, thereby optimizing the scooter’s overall energy efficiency and operational reliability.

Case studies involving electric mobility scooters equipped with the 8-inch 200mm × 45mm hub demonstrate superior performance consistency under diverse load conditions—from urban commuting to moderate off-road terrains. For instance, torque measurements indicate a 10%-15% increase in effective torque output during uphill climbs compared to models with smaller hubs.

Furthermore, user feedback highlights improved balance and ride smoothness attributable to optimized wheel contact and motor-hub synergy, underscoring the tangible impact of precise wheel hub sizing on real-world application.

Based on technical analyses and field data, adopting the 8-inch 200mm diameter × 45mm width hub configuration is highly recommended for mid-range electric mobility scooters seeking balanced performance and durability. When designing custom solutions, engineers should consider:

These strategies support scalable manufacturing while ensuring end-user satisfaction through reliable drive performance and longer vehicle lifespan.