Wet sidewalks, airport ramps after rain, freshly mopped hotel floors—these are small moments that can turn into big annoyances when a wheel loses grip. For smart luggage and auto-follow devices, the issue is even more critical: slipping doesn’t just feel unstable; it can disrupt tracking, steering, and overall user confidence.

The core culprit is often not “weak material,” but a physics effect: a thin layer of water forms between the PU tire and the ground, reducing real contact area. A water-guiding groove structure (drainage channels molded into the PU tread) is designed to break that water film—much like a windshield wiper creates a clear path on glass.

On a wet surface, a smooth or minimally patterned wheel can “float” microscopically on water. Engineers often call this the water film effect. Even a film thickness of 0.1–0.3 mm can noticeably reduce traction depending on speed, load, and floor texture.

Simple analogy: stepping on a wet tile with socks is not “dangerous” because the sock is weak—it's slippery because water creates a low-friction interface. A wheel tread without drainage behaves similarly.

For smart luggage wheels, the challenge is compounded by real-world travel conditions: alternating dry/wet patches, polished stone floors, paint markings on sidewalks, and cleaning detergents that further lower friction.

When a wheel carries weight, the contact patch compresses. With groove channels present, water is pushed laterally into these paths, reducing water pressure under the center of the patch. Less trapped water means more rubber-to-ground micro-contact, which is where usable friction comes from.

Grooves also add edges. On wet surfaces, edges matter because they “cut” the film and create localized high-pressure points. This improves stability during direction changes—especially relevant for auto-follow luggage that makes frequent micro-corrections.

Real travel routes are rarely uniform. A wheel might roll from textured asphalt to smooth tile in seconds. Drainage grooves reduce the “grip cliff” effect—sudden loss of traction when the surface becomes less porous and water cannot disperse naturally.

To make comparisons meaningful, engineers typically evaluate wheels using controlled wet-floor setups (standardized tiles or epoxy floors), fixed loads, and a thin water layer. Below are reference-level results consistent with what groove-based drainage designs aim to achieve.

| Test Condition | Metric (Typical) | Smooth PU Tread | PU with Water-Guiding Grooves | Practical Meaning |

|---|---|---|---|---|

| Wet ceramic tile, ~0.2 mm water film | Dynamic friction coefficient (μ) | 0.32–0.38 | 0.42–0.52 | Less “skating,” steadier roll on wet floors |

| Wet epoxy floor, detergent residue | Slip angle stability (relative) | Baseline | +18% to +28% | Better tracking for auto-follow steering corrections |

| Outdoor wet asphalt, light rain | Braking distance (relative) | 100% | 88%–93% | Shorter stopping feel when pulling/dragging luggage |

| Wet mixed surfaces (tile → paint line → tile) | Grip consistency (relative) | Baseline | +15% to +25% | Fewer sudden slips at transitions |

Note: Actual values vary with tread hardness (e.g., Shore A), wheel diameter, load, surface roughness, and water contamination level. These ranges are intended as realistic engineering references for wet-grip improvement.

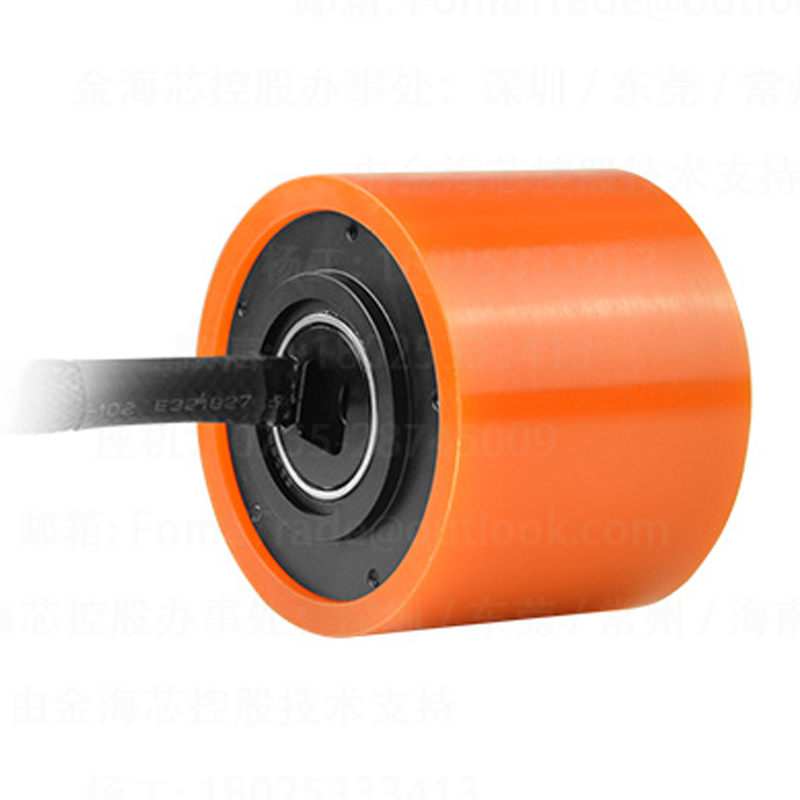

Anti-slip performance is often discussed like a single score. In reality, wheels for smart luggage and follow-me devices must balance grip, rolling noise, wear life, and aging resistance. PU is frequently selected because it can deliver a strong compromise across those demands.

After rain, smooth stone and painted markings can behave like low-friction layers. Drainage grooves help reduce the “first pull slip” when the wheel starts moving from rest—a moment when many users notice instability most.

Commercial cleaning areas introduce more than water: surfactants can lower surface tension and friction. Grooves provide a mechanical pathway for liquid displacement, improving traction consistency even when the floor is “wet-but-not-rainy.”

Smart systems rely on predictable wheel-ground interaction. When wheels slip, control algorithms may over-correct, causing jitter or path deviation. Better wet grip is not just about safety—it can also support smoother tracking behavior.

Not every groove pattern performs the same. For B2B buyers evaluating wheel modules for smart luggage, robotics, or utility carts, the following checks help separate cosmetic treads from functional drainage designs.

Look for channels that remain open under load (not shallow cosmetic lines). Functional designs typically balance groove width and depth so water can evacuate without collapsing.

A PU tread that is too hard may reduce wet grip; too soft may wear faster. Many mobility wheels operate effectively around Shore A 85–95, tuned to load and floor type.

Prefer suppliers who can provide wet-friction or slip testing references (surface type, water film thickness, load, speed). Without conditions, numbers are hard to compare.

Ask whether groove edges remain effective after rolling distance simulations. A practical benchmark is checking performance after 50–100 km equivalent rolling in mixed wet/dry conditions.

If wet-surface slip has become a recurring user complaint—or a hidden cause of returns—drainage-groove PU treads are a practical engineering path forward. The right wheel module can raise traction consistency without sacrificing wear life, helping products stay stable across rain, ramps, and freshly cleaned floors.

Specs, validation references, and integration notes for smart luggage, auto-follow devices, and mobility platforms.

Keywords: smart luggage wheels, water-guiding groove structure, PU tire anti-slip, anti-slip on wet pavement, wear-resistant luggage wheel tread