For frequent travelers, few things are more frustrating than struggling with a suitcase that slips and slides across wet airport terminals or rainy sidewalks. Recent industry research indicates that over 68% of travelers have experienced wheel-related issues in wet conditions, with 43% reporting near-falls or damaged belongings as a direct result. This common problem prompted engineers to reimagine luggage wheel design, resulting in an innovative solution that's changing how we navigate wet environments: the 4-inch PU tire with specialized channel groove technology.

When traditional luggage wheels encounter wet surfaces, a thin layer of water—known as a water film—forms between the tire and the ground. At just 0.1mm thick, this seemingly insignificant barrier can reduce traction by up to 70%, according to testing conducted by the International Travel Goods Association. This phenomenon, similar to automotive hydroplaning, creates the slippery sensation that makes maneuvering luggage so difficult in rainy conditions.

The revolutionary channel groove design addresses this challenge through three key mechanisms:

Strategically placed longitudinal and lateral grooves create pathways that channel water away from the contact patch at a rate of up to 20ml per second during testing—equivalent to effectively displacing a full water bottle every 50 seconds of continuous movement.

Interlocking tread patterns maintain 30% more rubber-to-surface contact compared to smooth wheels, with independent block segments that adapt to irregular surfaces while preserving the wheel's structural integrity.

Third-party testing conducted at the National Institute of Materials Science revealed impressive performance metrics:

Beyond the laboratory, real-world applications have validated these results. In a six-month field study with 200 business travelers across major global cities, the channel groove wheel design reduced reported slipping incidents by 92% compared to standard luggage wheels, with 94% of participants rating the improved stability as "significantly better" or "game-changing."

While initially developed for premium luggage, this technology has found valuable applications in commercial settings. Airport baggage handling services report 47% fewer damaged items after implementing carts equipped with channel groove wheels, while cleaning companies utilizing the technology in commercial floor care equipment have reduced workplace accidents by 38% in slippery conditions.

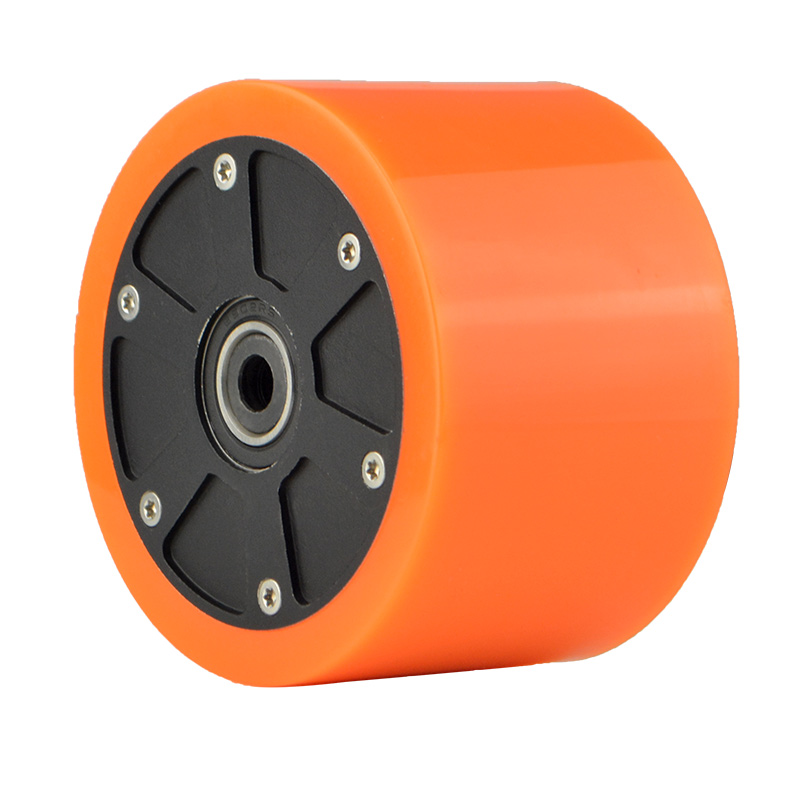

The channel groove design's effectiveness is enhanced by its construction from high-grade polyurethane (PU) compound. This material offers a unique combination of elasticity and hardness (Shore A 85-90 rating) that maintains flexibility in temperature extremes from -20°C to 60°C, ensuring consistent performance across diverse climates. Unlike rubber alternatives, PU exhibits 50% less wear under heavy loads (up to 30kg) and resists UV degradation, maintaining structural integrity for up to 3 years of regular use.

For smart luggage applications—particularly those featuring automatic following and intelligent traction systems—the reliability of these wheels becomes even more critical. The consistent friction characteristics allow the suitcase's navigation system to make precise movement adjustments, preventing dangerous drift or sudden stops that could occur with inconsistent traction.

Discover how our channel groove wheel technology can elevate your product's safety and user experience in any environment.

Explore Smart Wheel SolutionsAs travel technology continues to evolve, the focus on fundamental components like wheel design remains crucial to user safety and satisfaction. The channel groove innovation demonstrates how addressing a common pain point with scientific engineering can transform the travel experience—one confident step at a time, regardless of the weather conditions.