In the fast-paced world of global logistics, where every minute counts and operational continuity is non-negotiable, the reliability of material handling equipment directly impacts your bottom line. For warehouse managers operating in regions with high humidity, frequent rainfall, or cold storage environments, one silent threat looms large: slippery floors. A single skid or unexpected downtime can disrupt workflows, damage goods, and even compromise worker safety. Today, we explore how a specialized solution—PU grooved tires with water channel design—is transforming safety and efficiency in海外仓储 operations worldwide.

According to a 2023 report by the International Material Handling Equipment Association (IMHEA), 37% of warehouse accidents in humid regions are directly linked to tire-related slips on wet surfaces. These incidents result in an average downtime of 4.2 hours per occurrence and an estimated cost of $18,500 per incident when accounting for equipment repair, damaged inventory, and labor hours lost. For large-scale海外 distribution centers operating 24/7, this translates to potential annual losses exceeding $250,000.

| Performance Metric | Traditional Rubber Tires | PU Grooved Water Channel Tires |

|---|---|---|

| Coefficient of Friction (Wet Surface) | 0.35-0.45 | 0.68-0.75 |

| Abrasion Resistance (ASTM D395) | 50-70 mm³ loss | 15-20 mm³ loss |

| Service Life in Industrial Use | 6-8 months | 18-24 months |

| Water Displacement Rate | Limited (pooling issues) | 1.2 L/min (effective channeling) |

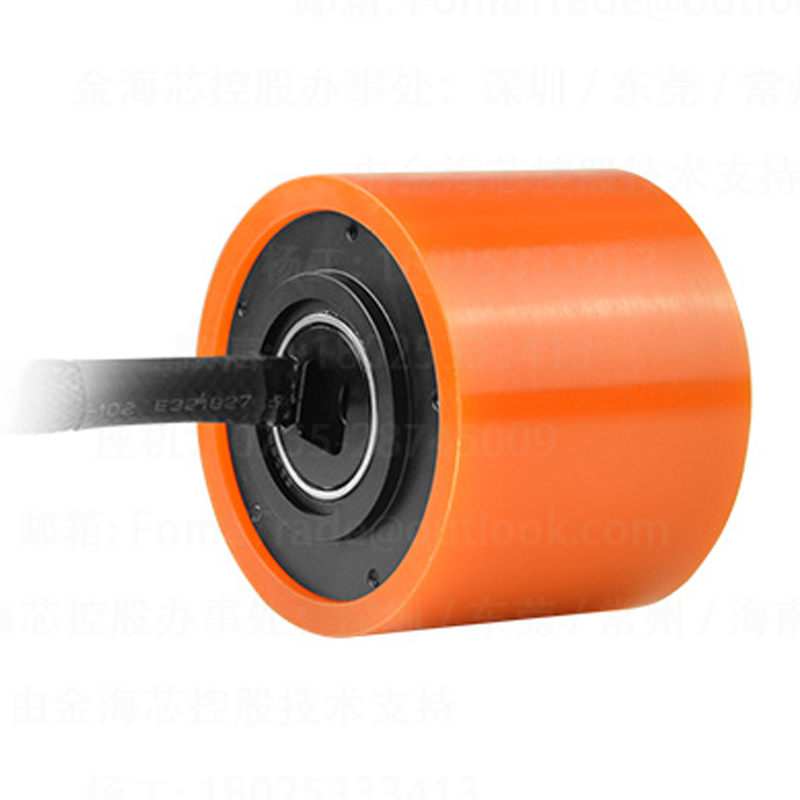

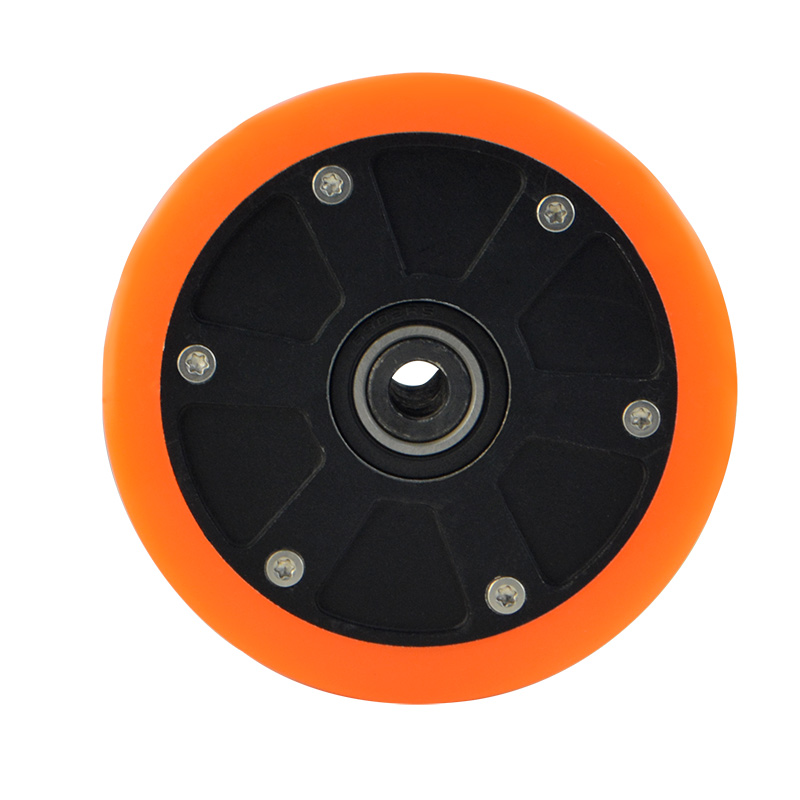

At the heart of this performance leap lies the innovative water channel structure. Unlike flat-surfaced traditional tires that allow water to accumulate between the tire and floor, creating a hazardous "hydroplaning" effect, the PU grooved design actively channels water away through precision-engineered grooves.

Formulated with a proprietary blend of polyurethane (Shore A hardness 85±3), these tires offer the perfect balance of elasticity and rigidity. Unlike rubber, which hardens and cracks in extreme temperatures (-20°C to 60°C common in warehouse environments), the PU compound maintains consistent performance, reducing tire replacement frequency by up to 67% compared to standard rubber alternatives.

"Third-party testing conducted by the Industrial Materials Research Institute (IMRI) demonstrated that the PU grooved tires maintained 92% of their original friction coefficient after 10,000 hours of operation under wet conditions, compared to just 58% for conventional rubber tires."

— IMRI Test Report #23-0478, April 2023

With a universal 105mm diameter × 42mm width specification and double-threaded axle design, these tires fit 95% of leading industrial cart models (Jungheinrich, Crown, Toyota, and more) without the need for custom adapters. This standardization reduces installation time from an average of 45 minutes per tire (for non-standard alternatives) to just 12 minutes, minimizing equipment downtime during maintenance.

Integrated Hall effect sensors provide real-time data on rotational speed (accuracy ±0.5 RPM) and tire wear, transmitting to your warehouse management system (WMS) via Bluetooth. This enables predictive maintenance scheduling, alerting operators when tread depth falls below 3mm—preventing unexpected failures and reducing emergency repair costs by an estimated 40%.

Take a moment to assess your current challenges:

If you answered "Yes" to any of these, the PU grooved water channel tires could deliver measurable improvements to your operations.

While premium tires represent a higher initial investment, the long-term savings are compelling. A case study with a major European logistics provider operating 200+ material handling carts showed a 3-year ROI of 247% through:

Every warehouse operation faces unique challenges—floor conditions, temperature ranges, load capacities, and equipment models vary widely across regions and industries. Our engineering team specializes in tailoring solutions to your specific needs, ensuring optimal performance from day one.

Our technical consultants provide on-site工况 assessment and 30-day trial periods for qualified customers

In Singapore's busy port warehouses, where monsoon season brings months of heavy rainfall, a leading logistics provider recently reported a 78% reduction in wet-floor incidents after upgrading to PU grooved tires. Their operations manager noted, "We used to schedule critical shipments around weather forecasts—now we maintain consistent throughput regardless of rain conditions."