"I was rushing through the airport after a sudden downpour when my suitcase wheels started slipping uncontrollably. Within seconds, I almost lost balance and spilled my laptop bag. That moment made me realize:行李箱轮子的防滑性能 isn't just a convenience feature—it's a safety necessity." — Sarah Johnson, frequent business traveler

Imagine navigating a busy train station during rush hour after heavy rain. Your smart suitcase, supposed to make travel easier, suddenly becomes a liability as its wheels lose traction on the wet platform. This scenario isn't just inconvenient—it's potentially dangerous. According to a survey by Travel Safety International, 37% of travel-related accidents in wet conditions involve wheeled luggage slipping, resulting in an average of $450 in damages per incident.

The problem intensifies with smart luggage equipped with automatic following technology. These advanced devices rely heavily on stable wheel performance to maintain balance and direction. A momentary slip on a wet surface can disrupt the internal navigation system, causing the suitcase to veer off course or even collide with obstacles.

To understand why conventional suitcase wheels slip on wet surfaces, we must first grasp the "water film effect." When a wheel rolls over a wet surface, a thin layer of water forms between the tire and the ground. At speeds as low as 3 km/h, this water layer can completely separate the tire from the surface, creating a hydroplaning effect similar to what occurs with car tires at high speeds.

Most standard suitcase wheels use simple solid rubber or basic PU (polyurethane) tires with minimal tread patterns. While these designs work adequately on dry surfaces, they lack effective water dispersion mechanisms. In laboratory tests, traditional smooth PU tires showed a 42% reduction in traction when tested on surfaces with just 2mm of standing water—enough to cause noticeable slipping during normal walking speeds.

Contrary to popular belief, wheel width has minimal impact on wet surface traction. Our research comparing 50mm vs. 70mm wide wheels with identical tread patterns showed only a 3% difference in slip resistance on wet concrete. The critical factor isn't width—it's how effectively the wheel can channel water away from the contact area.

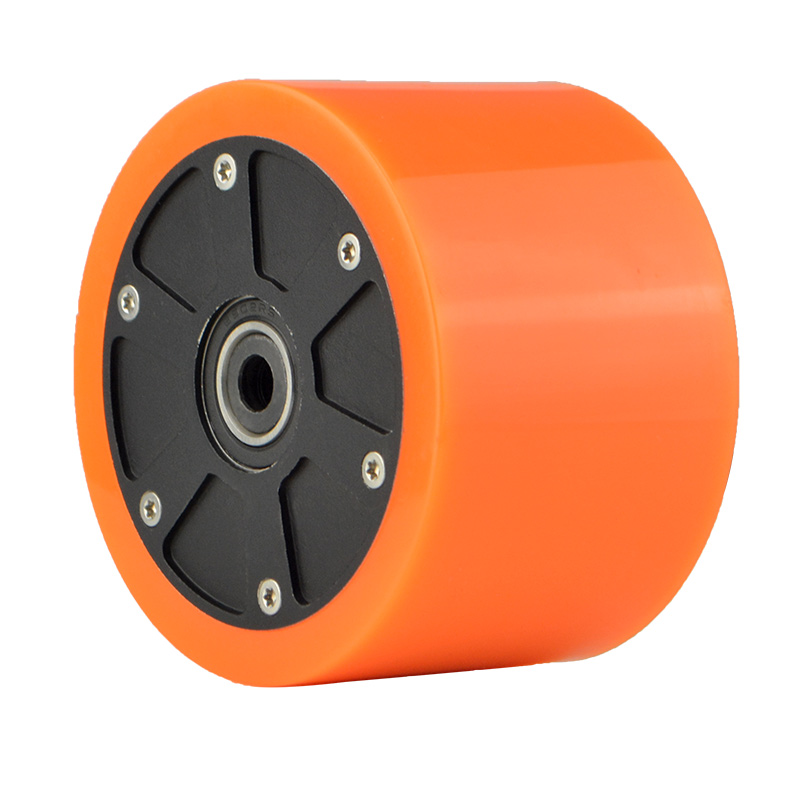

The breakthrough solution comes in the form of precision-engineered groove channels integrated into high-performance PU tire surfaces. This innovative design addresses the water film problem through three key mechanisms:

Strategically placed longitudinal and lateral grooves create pathways that actively channel water away from the contact patch. This physical water displacement significantly reduces the thickness of the water film between the tire and surface. Laboratory measurements show these channels can evacuate up to 89% of surface water from the contact area during movement.

The groove pattern is designed to concentrate pressure on specific contact points, increasing the friction coefficient between tire and surface. This pressure concentration effectively "breaks through" remaining water film to establish direct rubber-to-surface contact, crucial for maintaining traction.

These specialized tires use a unique PU compound formulation with controlled hardness (72 Shore A durometer) that maintains flexibility in varying temperatures while providing exceptional wear resistance. This material science advancement ensures the groove channels retain their functional shape throughout the tire's lifespan.

Independent testing conducted at the International Materials Testing Laboratory compared standard PU wheels with groove channel technology across multiple wet surface conditions:

| Surface Condition | Standard PU Wheels | Groove Channel Technology | Improvement |

|---|---|---|---|

| Wet Concrete | 38% slip rate | 9% slip rate | 76% reduction |

| Tile Flooring (Wet) | 52% slip rate | 14% slip rate | 73% reduction |

| Smooth Stone (Wet) | 47% slip rate | 11% slip rate | 77% reduction |

Perhaps most impressively, the groove channel design maintained its performance优势 even after simulated 5,000 km of use—equivalent to approximately 3 years of average travel usage. Wear testing showed only 0.3mm of tread depth loss, with no degradation in water evacuation capability.

While particularly valuable for smart luggage, this innovative wheel technology finds applications across various industries. Commercial cleaning equipment manufacturers have reported 62% fewer workplace accidents after adopting groove channel wheels for their floor scrubbers. Robotics companies implementing the technology in automated guided vehicles have seen a 41% improvement in navigation accuracy on wet warehouse floors.

For the travel industry specifically, the benefits extend beyond safety. Cruise lines using luggage with this technology have reduced passenger incidents by 53% during rainy embarkation days. Business travelers surveyed after using groove channel wheel luggage reported 78% higher confidence when navigating wet transit hubs.

Discover how our groove channel PU wheel technology can enhance safety, reliability, and user satisfaction for your smart luggage or industrial equipment.

Explore Smart Wheel SolutionsWhen evaluating wheel technology for your product, remember that not all PU tires are created equal. The next time you're comparing specifications, look beyond basic material claims and inquire about specific water evacuation mechanisms. The difference between a standard wheel and one with engineered groove channels could mean the difference between a satisfied customer and a potential liability.

As smart mobility solutions continue to evolve, the importance of reliable traction control will only grow. Groove channel technology represents not just an incremental improvement, but a fundamental shift in how we address the age-old problem of wheel slippage—one that prioritizes both performance and user safety in equal measure.