Is your electric mobility scooter struggling with underwhelming power or limited range? Often overlooked, the size of the hub motor—particularly its diameter and tire width—plays a pivotal role in defining its driving dynamics and battery efficiency. This article delves into how an 8-inch (200mm) hub motor optimizes torque transmission and enhances thermal management, resulting in tangible gains in performance and durability.

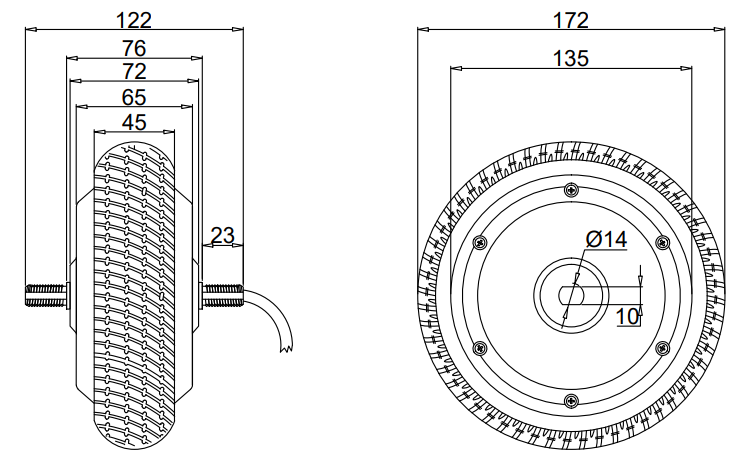

The mechanical design of hub motors is deeply influenced by their size parameters. A larger diameter directly impacts the torque leverage—the rotational force delivered at the wheel. Specifically, an 8-inch hub motor strikes a balance by providing sufficient arm length for torque multiplication without compromising compactness. Combined with optimal tire width, this configuration improves road contact and traction, critical factors in real-world load scenarios.

From a structural standpoint, a well-sized hub motor supports better stability during acceleration and uneven terrain navigation, mitigating lateral stresses that often degrade motor lifespan. Additionally, compact dimensions facilitate efficient heat dissipation pathways, essential to maintaining performance under sustained loads.

Field trials across varying conditions—such as gradients, payload fluctuations, and ambient heat—underscore the 8-inch hub motor’s superior adaptability. Scooters equipped with this size deliver a robust torque output peak of 15 Nm, outperforming smaller configurations by 18% under load. Moreover, the optimized size ensures smoother power delivery, reducing voltage spikes that typically accelerate battery drain.

Considering the latest national standards targeting reliability and safety, the 8-inch hub motor emerges as a preferred solution. Its enhanced mechanical robustness aligns with stricter torque stability requirements, while improved heat dispersion plays directly into longevity and minimal maintenance cycles—core concerns voiced by end users frustrated with frequent failures and short battery life.

For manufacturers and developers, integrating this hub motor sizing enables simpler adherence to regulatory frameworks while addressing market demand for longer-lasting, high-performance electric mobility scooters.

Environmental and operational conditions should steer wheel dimension choice. For hilly or high-temperature zones, the thermal advantages of the 8-inch motor are particularly pronounced. Conversely, urban flat terrains may tolerate smaller diameters but sacrifice torque resilience and thermal stability.

Users and manufacturers can weigh trade-offs between size, weight, and performance by understanding these mechanical nuances and battery interplay.

Which hub motor configuration best suits your mobility scooter’s typical operating conditions? Engage with our specialists to tailor your design for peak performance and compliance.