Are you worried that poor maintenance of your electric camper van's motor could lead to power decline or safety hazards? In this article, we'll guide you through the entire process of motor maintenance, from cleaning the motor housing to checking the transmission system. We'll also analyze the key points of anti - rust treatment at the biaxial thread connection and the collaborative state monitoring of the battery and controller. This will help novice owners establish a scientific maintenance awareness, improving the durability and safety of your equipment.

Let's start with the basics. The first step in maintaining your electric camper van's motor is cleaning. You should regularly clean the motor housing to prevent dust and debris from accumulating. Use a soft brush or a compressed air can to remove dirt from the surface. This simple step can significantly reduce the risk of overheating caused by poor heat dissipation.

Next, check the tightness of the key components. Loose parts can lead to abnormal vibrations and even damage the motor. You can use a torque wrench to ensure that all bolts and nuts are tightened to the specified torque. For example, the bolts connecting the motor to the frame should be tightened to about 20 - 25 Nm.

Another important aspect is to monitor the temperature rise of the motor. An abnormally high temperature could indicate a problem with the motor or the transmission system. You can use an infrared thermometer to measure the temperature of the motor housing. If the temperature exceeds 60°C during normal operation, it's time to stop and check for issues.

The biaxial thread structure of your electric camper van offers excellent stability, especially on rough terrains. However, it's also more prone to rust, which can affect its performance. Here's a tip: Apply a layer of anti - rust grease to the biaxial thread connection. This will prevent moisture and oxygen from reaching the metal surface, reducing the risk of rust.

Regularly inspect the biaxial thread for any signs of wear or damage. If you notice any loose threads or abnormal wear, it's advisable to replace the parts as soon as possible. This will ensure the safety and stability of your vehicle.

The battery and controller of your electric camper van work together to provide power to the motor. Monitoring their collaborative state is crucial for the proper operation of your vehicle. You should regularly check the voltage and current of the battery and controller. Any significant deviation from the normal values could indicate a problem.

⚠️ When performing any maintenance on the battery or controller, make sure to disconnect the power first. This will prevent electric shock and other safety hazards.

One common problem is foreign object jamming in the transmission system. If you hear abnormal noises or feel a decrease in power, it could be due to a foreign object getting stuck in the gears or belts. In this case, you should stop the vehicle immediately and remove the foreign object.

Another issue is abnormal heating. As mentioned earlier, an overheated motor or controller can be a sign of a serious problem. Check for loose connections, damaged wires, or overloading. If you can't identify the problem, it's best to consult a professional.

By following these maintenance tips, you can significantly improve the performance and safety of your electric camper van. Regular maintenance not only extends the lifespan of your equipment but also provides a more enjoyable camping experience.

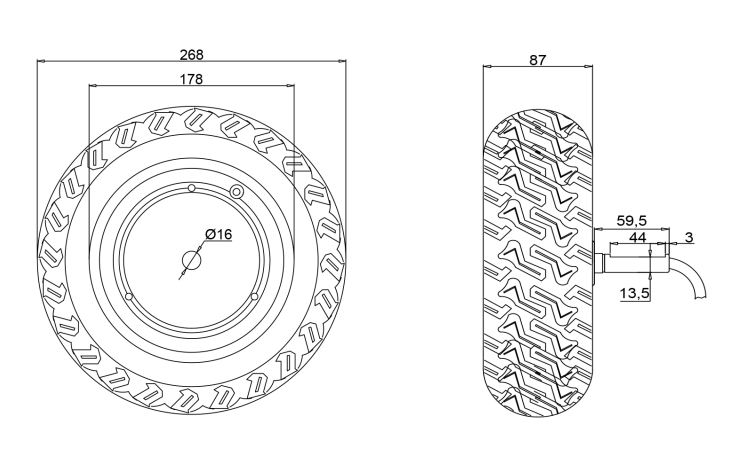

Ready to take your electric camper van maintenance to the next level? Our products offer exclusive compatibility with 165mm wide tires and require no secondary processing for easy installation. Click here to learn more about our high - quality maintenance products and solutions!