Brushless Hub Motor Troubleshooting Guide: Quickly Identify and Resolve Power Loss and Unusual Noise

Brushless hub motors are extensively used in flatbed carts, yet issues like power loss and unusual noise frequently challenge operators. This article analyzes common fault causes from multiple perspectives including loose installation, bearing wear, and controller abnormalities. It provides step-by-step diagnostic methods for quick issue localization and targeted repair solutions. Leveraging JinHaiXin's practical experience, this guide aims to assist logistics and warehousing professionals in effective troubleshooting, minimizing downtime, and enhancing equipment performance.

Brushless Hub Motor Troubleshooting Guide: Quickly Identify and Resolve Power Loss & Unusual Noises

As a maintenance technician managing flatbed trolleys equipped with brushless hub motors, you often face challenges such as reduced power output or strange noises affecting operational efficiency. This guide provides a systematic approach to diagnosing and resolving these common faults efficiently, helping you minimize downtime and ensure smooth logistics operations.

1. Symptoms Classification: Recognizing Key Fault Indicators

Start by accurately identifying the nature of the motor issue. Typical symptoms include:

- Power reduction: Noticeable decline in motor torque or acceleration.

- Abnormal noise: Grinding, clicking, or humming sounds during operation.

- Overheating: Excessive motor temperature beyond normal operating range.

2. Common Cause Analysis: Mechanical, Electrical & Environmental Dimensions

The root causes can often be categorized into three critical areas:

- Mechanical issues: Loose mounting components, worn bearings, or shaft misalignments.

- Electrical faults: Controller malfunction, voltage fluctuations, or wiring defects.

- Usage environment: Excessive dust, moisture intrusion, or overloading conditions.

3. Step-by-Step Diagnostic Process for Rapid Fault Location

Follow this practical checklist to systematically narrow down the problem:

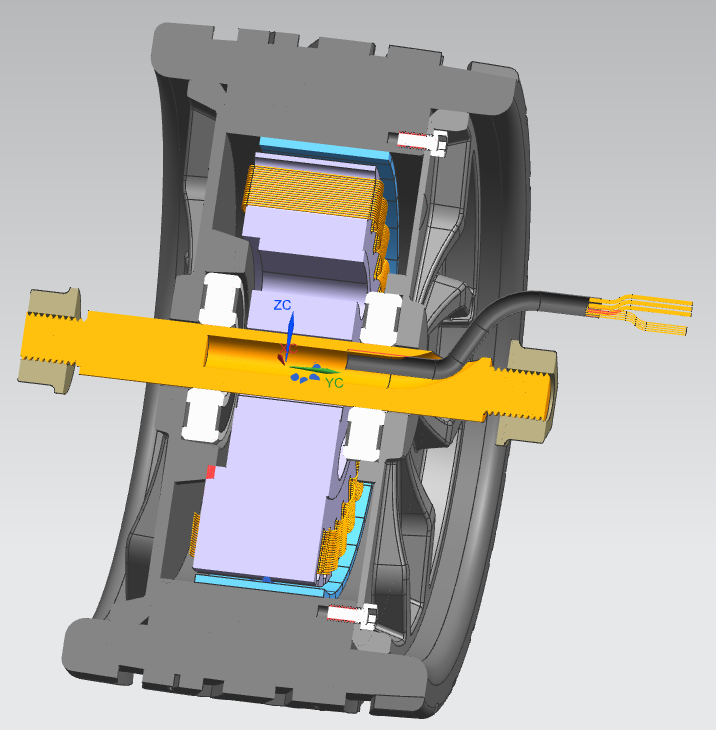

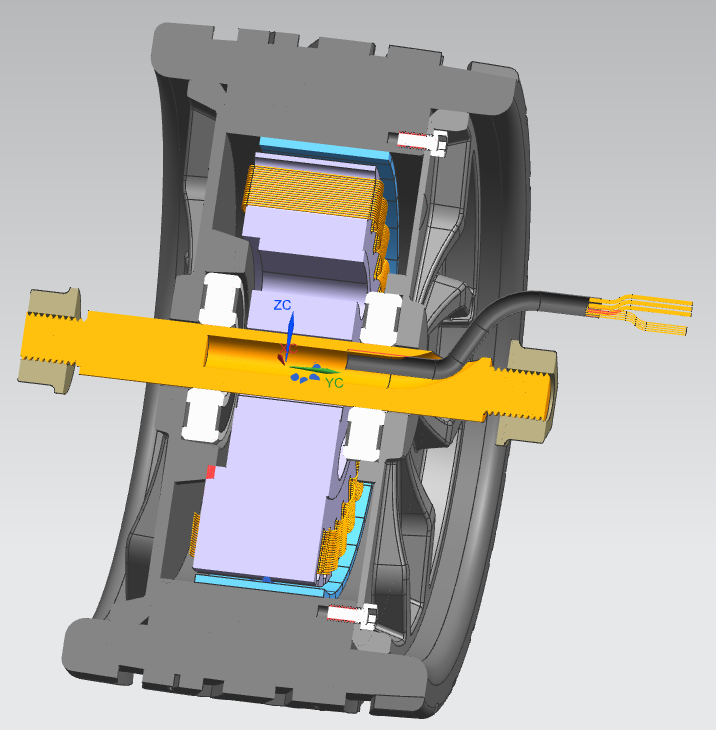

- Inspect the mounting screws and shafts: Our brushless hub motors feature a dual-thread shaft design that guarantees secure installation. Ensure all fasteners are tight to eliminate abnormal vibrations.

- Measure voltage stability: Use a multimeter to verify consistent power supply levels; voltage sags or spikes can impair motor function.

- Monitor noise sources: Pay close attention to unusual sounds; grinding often points to bearing wear, while humming might suggest electrical issues.

Adhering to this flow reduces guesswork and enables you to address failures before they escalate.

4. Practical Repair & Preventive Measures

Once diagnosed, apply these targeted solutions:

- Tighten or replace mounting hardware: Always utilize the double-threaded shaft specification to maintain robust stability during heavy-load use.

- Replace worn bearings: Prioritize quality industrial-grade bearings to prolong motor life and reduce noise.

- Update or recalibrate controllers: Faulty controllers can be reset or swapped to restore efficient electrical management.

- Adjust operation conditions: Avoid excessive overload and maintain clean environments to prevent premature wear.

Routine maintenance schedules aligned with these practices significantly decrease unexpected failures.

5. Customized Support & Component Services

For sustained reliability, partnering with a provider that offers specialized technical support and custom-fit parts is invaluable. Our experience with brushless hub motors tailored for industrial logistics equips you with:

- Expert remote diagnostics assistance

- Custom-designed components to fit diverse trolley models

- Preventive maintenance training for operational teams

Professional backing not only reduces downtime but also optimizes your fleet’s performance and lifespan.