Selecting the right brushless hub motor for an 8-inch (200mm) flatbed cart can greatly influence the vehicle's efficiency and longevity. This detailed guide dissects the practical considerations necessary to match a dual-threaded axle design with an 83mm tire width and a 100mm hub opening, ensuring optimal compatibility and performance.

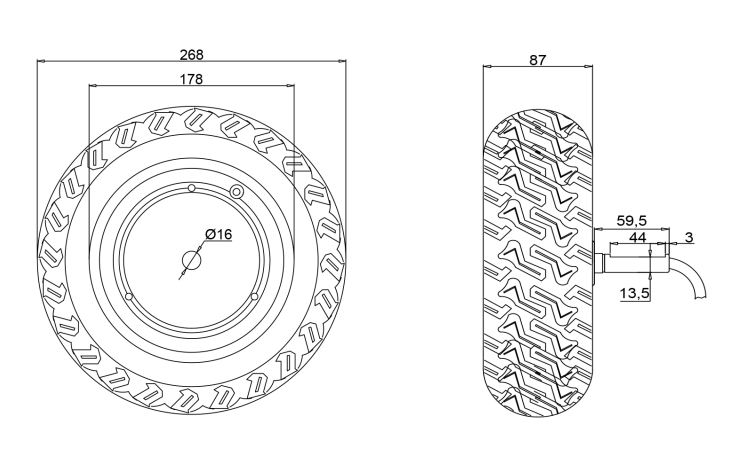

The foundation of proper motor selection rests on thorough knowledge of size, axle structure, and tire width — critical variables that affect installation quality and operational stability. For an 8-inch (200mm) brushless hub motor, the axle's dual-threaded design provides robust fastening points on both sides, ensuring steady connection within the wheel assembly and minimizing mechanical play under load.

The tire width compatibility is equally vital; an 83mm wide tire paired with a 100mm hub opening allows for optimal rim seating and tire inflation, preventing premature wear and maintaining smooth motion across variable payloads.

Industrial environments place diverse demands on flatbed carts. Factors such as payload weight, surface type, and operational frequency must influence motor choice. For instance, typical maximum payloads range between 150–300kg; pairing this with a high-torque 8-inch hub motor featuring an IP65-rated protective casing enhances durability and performance under harsh conditions.

Additionally, brushless motors with advanced heat dissipation structures reduce thermal build-up, thus preventing motor degradation in sustained operations. Understanding your specific use-case scenarios, such as inclines or uneven surfaces, enables you to select an appropriate motor winding configuration and voltage rating.

The dual-threaded axle system offers several advantages over single-thread variants:

Installation Steps:

Common challenges during installation include thread misalignment, incorrect torque application, and tire-hub mismatches causing unsafe ride qualities. To circumvent these, always:

Advanced manufacturing processes, such as CNC-machining for precision axles and high-quality casting for motor housings, substantially increase mechanical reliability. The integration of IP65 or higher-rated seals prevents dust and water ingress — critical for devices exposed to industrial dust and moisture.

Additionally, the use of corrosion-resistant alloys and thermal-resistant coatings extend motor life beyond typical 5,000 operational hours to upwards of 15,000 hours under standard industrial use.

Designing a flatbed cart with the right motor installation ensures not only dependable performance but also user safety and cost-effective maintenance cycles. Whether for warehouse logistics or outdoor transport, matching the motor assembly precisely to your cart's specifications is paramount.